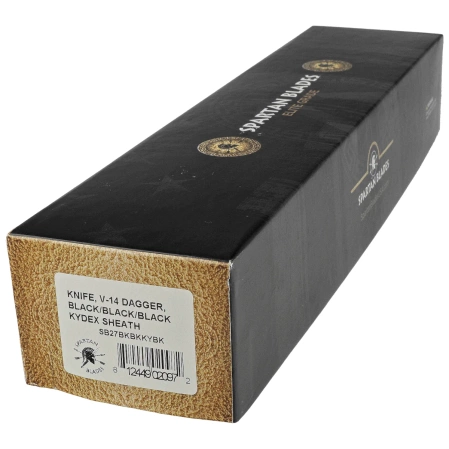

Spartan Blades George V-14 Dagger Knife Black G10, Black PVD MagnaCut by Les George (SB27BKBKKYBK)

- George V14 Dagger Black G10, Black PVD, Special forces dagger designed by well-known knifemaker Les George. Strong full tang construction made of high-quality CPM MagnaCut steel, G10 composite handle, multi-position kydex sheath.

613,88 €

613,88 €This product is intended for use only by adults with knowledge and experience in handling sharp cutting tools. Improper use of the knife can result in serious injuries. The blade is extremely sharp and can easily cut through skin and tissue; therefore, extra caution should always be exercised while cutting, and hands should be kept away from the cutting edge. To prevent the knife from slipping, it is recommended to cut on a stable, non-slip surface and avoid excessive force, which may cause uncontrolled blade movement.

Leaving the knife on the edge of a table, countertop, or in easily accessible places—especially where children are present—poses a significant safety risk. The knife should always be properly secured after use, ideally by placing it on a stable surface or storing it in designated knife blocks, protective sheaths, or magnetic strips. The knife should never be used for tasks it is not designed for, such as opening cans or prying objects, as this can damage the tool and lead to dangerous accidents.

A dull blade increases the risk of injury, as it requires more force and is more likely to slip from the material being cut. Therefore, it is essential to sharpen the knife regularly to maintain optimal sharpness. Additionally, proper cleaning and drying of the knife are necessary to prevent corrosion and bacterial growth. Periodic inspection of the handle and blade is recommended to check for cracks, chips, or looseness. If any damage is detected, the knife should be repaired or replaced immediately.

When using the knife, focus solely on the task at hand—avoid talking on the phone, watching television, or other distractions while cutting. Ensure proper lighting in the workspace for better visibility and control. Please note that some countries or regions have laws restricting the ownership and carrying of knives. Before purchasing or using this knife, verify that its use is legal in your location according to applicable regulations.

Following these safety guidelines will help ensure safe and effective knife use, minimizing the risk of accidents and extending the lifespan of the tool.

George V-14 Dagger Black G10, Black PVD is a high-end tactical dagger designed by renowned knife maker Les George. The full tang construction is made of expertly-appreciated CPM MagnaCut steel, which ensures high corrosion resistance and reliable blade durability even in extreme conditions. The blade is coated with black PVD, which minimizes light reflection and effectively protects the surface from mechanical damage. The handle is made of durable, matte G10 composite and guarantees a secure grip with or without gloves. The special surface texture of the handle prevents the knife from accidentally slipping out during intensive use. The set includes a sturdy molded kydex sheath that allows the knife to be attached to tactical equipment in various positions. Thanks to the combination of advanced materials and professional design, this dagger is highly regarded by personal protection officers, uniformed services and enthusiasts of the highest quality tactical solutions.

Les George is an American knife maker who started his career in 1992, gaining experience as a soldier in the United States Marine Corps. In his workshop in Texas, he creates blades that stand out for their precision workmanship, solid construction and ergonomic shape. By combining classic craft techniques with contemporary metalworking methods, George produces knives with matt surfaces, smooth, clear edges and durable handles. His designs are valued by collectors and professionals alike and are characterized by minimalist elegance and reliability, resulting from the careful selection of steel and a precisely controlled process of hardening, grinding and sharpening.

Spartan Blades - In 2008, in a historic barn in Aberdeen, North Carolina, two retired non-commissioned officers of the United States Army Special Forces - Curtis Iovito and Mark Carey - combined more than 40 years of military experience to found Spartan Blades, a company specializing in the production of high-quality knives for both military and civilian use. Each knife, reflecting their constant pursuit of perfection, is carefully designed and made from the finest materials, such as CPM MagnaCut steel and titanium. Thanks to its collaboration with renowned designers, including William W. Harsey, Jr., Spartan Blades has won numerous industry awards, including the prestigious title of “American Made Knife of the Year” for the Spartan-Harsey Folder model in 2016. In 2019, following the merger with KA-BAR Knives, Spartan Blades expanded its production capabilities, introducing three product lines: Gold, Silver and Bronze, tailored to the diverse needs of customers. Today, Spartan Blades remains synonymous with excellence in the world of knives, combining military precision with the highest craftsmanship.

CPM MagnaCut – powder stainless steel produced in the Crucible® Particle Metallurgy (CPM) process, hardened to 60.5-62.5 HRC. The high vanadium content of 4.0% (V), molybdenum content of 2.0% (Mo) and niobium content of 2.0% (Nb) guarantee a level of precision and purity that is unmatched by more “conventional” steels. Specially designed and developed for blade production by Larrin Thomas, it meets all the requirements of knife enthusiasts. Thanks to CPM MagnaCut, it has been possible to create a steel that combines the unique properties of knife steels like no other. The result is a blade material that offers an extraordinary balance between wear resistance, strength and corrosion resistance. Currently, there is no other steel on the world market that offers a comparable combination of excellent properties. This unique steel is produced in the American steelworks of Crucible® Industries.

Vacuum & Cryogenic - the steel undergoes a specialized heat treatment process involving two key stages. Vacuum Heat Treatment the steel is hardened in a vacuum environment, which minimizes oxidation and ensures more uniform metal properties. This process increases the strength and structural integrity of the steel. Double Cryogenic Treatment: After heating, the steel is rapidly cooled to extremely low temperatures, often below -100°C (-148°F). This transformation changes the residual austenite into martensite, significantly increasing the hardness, wear resistance and overall durability. Thanks to these advanced processes, the steel ensures exceptional performance, offering both razor-sharp edge retention and extraordinary blade durability.

PVD (Physical Vapor Deposition) - the surface resistance of the blade and cutting edge is increased by vacuum deposition, which is used to deposit thin layers by condensing the vaporized form of the desired material on the surface of the workpiece. The coating method involves a purely physical process, such as high-temperature vacuum evaporation and subsequent condensation. The applied coating has a very high hardness, which significantly increases the blade's resistance to rust and abrasive wear.

Blade - classic Dagger profile, D/E (Double Edge) sharpened on both sides, black PVD coating. The thickness of the blade in combination with the symmetrical flat grind provides excellent cutting properties and high durability. The centrally placed grain strengthens the structure. The guard on both sides protects the hand from sliding onto the blade.

Handle - Grips made of G10 composite, a material with extremely high mechanical strength and virtually complete resistance to weather conditions and chemicals, textured for improved grip. The profiled shape ensures a comfortable, secure grip even with wet hands. The forefinger groove on the front improves grip. The protruding part of the tang can be used as an improvised window breaker.

Sheath - made of kydex plastic in black. Prevents the knife from falling out and facilitates quick access. MOLLE compatible, allows you to attach the sheath to M.O.L.L.E. (Modular Lightweight Load-carrying Equipment) straps or carry it on a belt or equipment. A set of holes on the edge allows you to adjust the way you carry it to your individual needs.

Technical data:

Product number: SB27BKBKKYBK

Product name: George V-14 Dagger Black G10, Black PVD

Overall length: 292.0 mm / 11.5”

Blade length: 171.0 mm / 6.75”

Blade thickness: 5.5 mm / 0.25”

Handle length: 121.0 mm / 4.75”

Handle thickness: 25.9 mm / 1.02”

Weight: 263.0 g / 9.28 oz

Blade material: CPM MagnaCut

Blade hardness: 61-63 HRC

Blade grinding: Hollow

Blade finish: Black PVD coating

Handle material: G10

Handle finish color: Black

Sheath: Kydex

Accessories: M.O.L.L.E. adapters

Designer: Les George

Brand: Spartan Blades

Manufacturer: Spartan Blades

Country of origin: USA

Development: Sharg® company